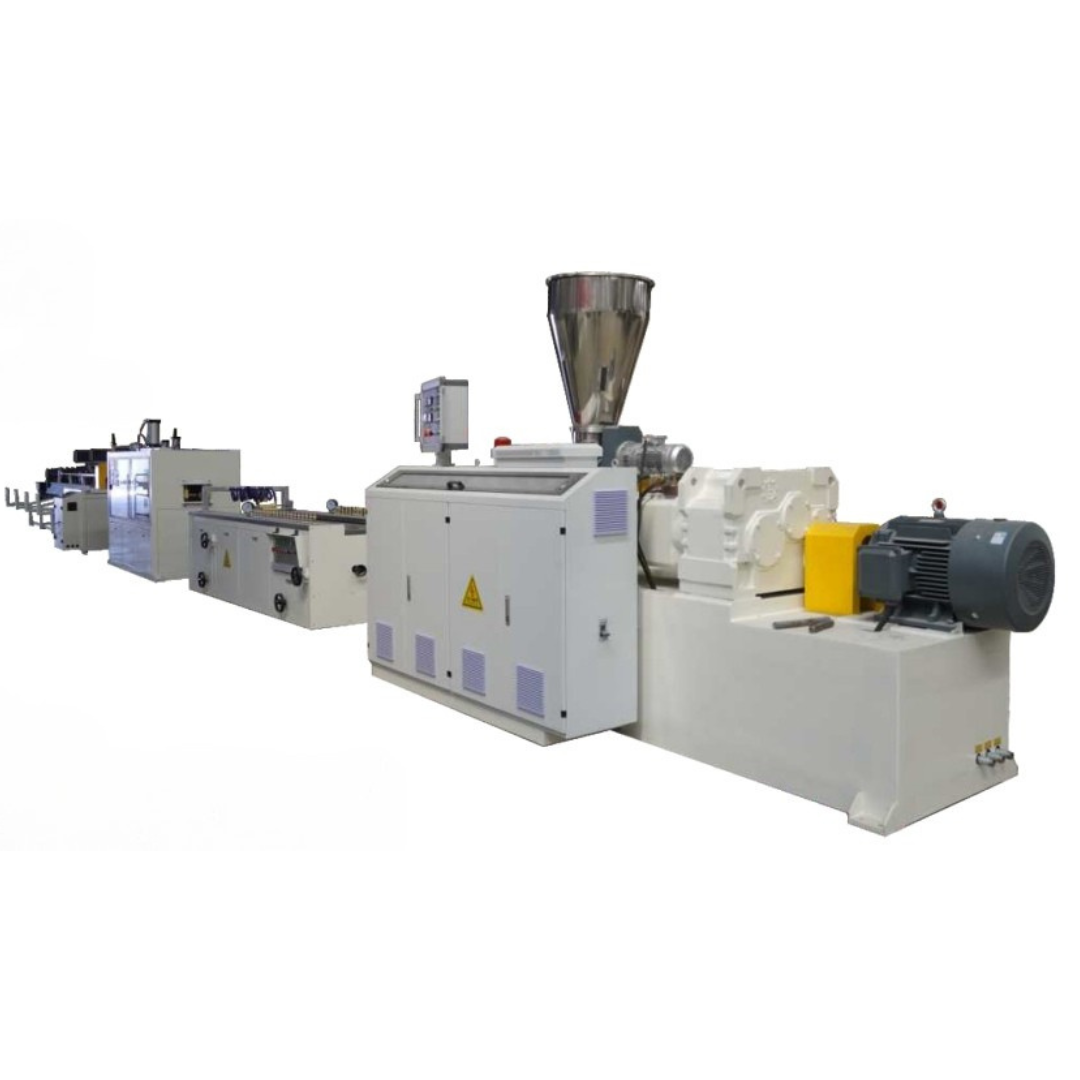

PVC Ceiling and Wall Panel Production Line

Features and Uses

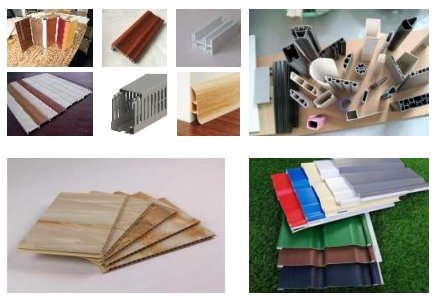

This machine can be used to produce

PVC Ceiling & Wall Panel, PVC Corner Profiles, PVC Cable Trunking, PVC Corner Bead and etc.

Description

Technical Parameter

| Model | 48/51 | 53/55 | 65 |

|---|---|---|---|

| Applicable product width (mm) | <300 | <400 | 200–603 |

| Extruder | SJSZ48/113 or SJSZ51/105 | SJSZ55/110 or SJSZ53/128 | SJSZ65/132 or SJSZ65/138 |

| Capacity (m²/24 hour) | >800 | >1200 | >1600 |

Main Features of PVC ceiling and wall panel machine:

-

extruder adopts PVC ceiling panel dedicated screw, make sure best plasticizing effect, further make sure best final product shape

-

extruder speed and haul off speed controlled by ABB frequency inverter, saving power and easy adjusting speed

-

extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level

-

the amount of filled calcium can be from 50phr to 250phr, easy to control product cost and quality.

-

Equipped with infrared tracking device which can eliminate the problem of fluctuation of extrusion flow rate, further can make sure get best product

-

lower power consumption, it can save 25-30% electricity power consumption comparing with most same kind PVC wall panel machine

-

economical price, suitable for large scale investment.

Reviews

There are no reviews yet.